September 10 – Nuclear power plants should be considered immune to meltdowns and vulnerable to bad actors trying to collapse the system.

Operations and maintenance (O&M) costs incurred to meet stringent safety and security requirements can make it difficult for US utilities to keep nuclear power plants operating at rates competitive with natural gas-fired power plants.

According to research by the U.S. Department of Energy (DOE), the cost of operating and maintaining nuclear power plant safety accounts for about 7% of the total cost of generating electricity, with labor accounting for half of this cost.

This analysis is part of the U.S. Department of Energy’s 2020 Young Water Reactor Sustainability Initiative, which was established to support research to reduce operation and maintenance costs through direct modeling and simulation studies.

Research shows that in many nuclear power plants, the number of physical security personnel is about 20% of the entire workforce.

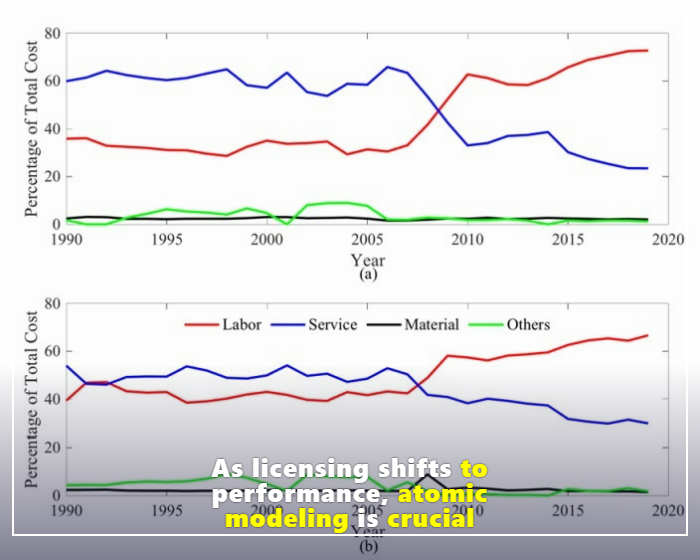

According to the analysis, labor costs account for more than 60% of the total physical security budget, and this proportion has been rising steadily since 2008, indicating that physical security systems have shifted to a more labor-intensive approach.

Chart: Physical security cost as a proportion of total cost

However, these costs may change as the Nuclear Regulatory Commission (NRC) changes its approach to next-generation reactors.

Current regulations are mostly prescriptive – factories must have a certain number of barriers, all at a specific height, and have a certain number of armed response personnel on site.

The new rules proposed by the NRC focus more on performance-based requirements, which could provide developers more flexibility in plant management and impact safety and security costs.

New method

The new rules will review each plant’s plans individually to determine whether the developer’s proposed wall, combined with other aspects of the physical security system, is sufficient to deter opponents.

Current requirements are also intended to prevent sabotage, defined as core damage resulting from local fuel meltdown, though the new rulemaking is intended to focus on the radiation dose expected at the exclusion limit as a result of an attack.

This new approach focuses more on accurately modeling the reactor design to accurately mitigate the consequences of an incident, rather than focusing only on avoiding specific events, such as core damage.

“It’s the performance-based requirements that completely changed the paradigm for advanced small modular reactors, so we went into more modeling and simulation,” said Christopher Chavez, regulatory development and licensing engineer at Idaho National Laboratory (INL).

“Instead of using safety procedures to prevent core meltdowns, we are now focusing on the performance of the reactor in response to safety events.”

For exclusive nuclear insights, sign up for our newsletter.

The laboratory’s work pioneered “safety by design” and developed the Event Modeling Risk Assessment using Linked Diagrams (EMRALD) software to integrate tools for simulating power plant scenarios.

Combining EMRALD with other software tools such as thermal-hydraulic tools and timelines related to adversary and reaction force actions results in security modeling and analysis using the dynamic EMRALD framework (MASS-DEF).

An example of using the MASS-DEF framework is the modeling of a water replenishment system designed to provide an additional 24 hours to the reactor core in the event of a safety incident.

From a safety point of view, 24 hours may be sufficient, but from a security point of view, if the simulated armed response time of this reactor exceeds 24 hours, a larger tank may be required.

“We’re entering a new world of physical security, so modeling and simulation are critical because we’re talking about doing all of this rigorously during the design phase,” Chavez said.

With accurate, performance-based modeling, the number of armed responders needed to protect a plant can be reduced.

By eliminating just one guard from the payroll, the utility could save millions of dollars over the plant’s 40-year permitting period, Chavez said.

passive protection

At the U.S. Department of Energy’s Argonne National Laboratory (Argonne), researchers are working on a half-scale model of the reactor system, known as the Natural Convection Shutdown Heat Removal Test Facility (NSTF), which allows them to study the ability to operate a passive safety system to cool the reactor without compromising reactor cooling.

The data collected meets the industry’s national standards for quality assurance, or National Quality Assurance-1 (NQA-1), and is shared with developers, suppliers, and regulators to validate computational models and guide the licensing of new reactors and nuclear power plants.

While a passive safety system is not designed to replace a human operator, it does add an extra layer of safety in the worst case scenario.

“If you lose power, you’re going to run out of options, and some of your systems will be dependent on power-based valves being closed or switches being flipped.” There’s nothing to worry about with the system.

“If you lose power and lose control of the switch or valve, it doesn’t matter because you have this extra layer of protection that keeps the coolant flowing no matter what.”

As high-tech sensor systems develop, modeling becomes more accurate, but predictive systems can face challenges, especially in edge cases.

One example is when water flowing through a system begins to boil, Jessica said, this is a complex chaotic phenomenon that is difficult to model due to changes in pressure waves and fluid loss.

Argonne National Laboratory is currently developing a data set that investigates various reactions to boiling water, allowing modelers to use the data to validate their models.

Standardized, shareable data means that certain security tests don’t need to be performed individually by developers, reducing costs for everyone.

“One of our major contributions to driving down existing costs is that we have the facilities, we have the data that’s being generated right now, and we’re working with them to make sure that we do what they need to do next, so they don’t have to spend any money to do it,” Jasika said.

The views expressed are solely the author’s own. They do not reflect the views of Askume News, which is committed to integrity, independence and non-partisanship in accordance with the principles of trust. Askume Events is part of Askume Professional, which is owned by Thomson Askume, and operates independently from Askume News.